Design of Traditional Lime Kilns of Tamilnadu

Lime, a calcium-containing material, was once an inevitable building material in the construction industry. From mortar to plaster, lime served its ultimate purpose in ancient architecture. There have been clear traces of usage of lime in Keeladi, as old as the Sangam Era, to build water-holding structures. The bricks of Keeladi too are studied to find content of lime upto 7%, indicating the early use of lime as a stabilizer.

Choosing the lime stones

Lime stones can be divided into two categories : Hydraulic lime and Non-hydraulic lime. The difference between these two types is the presence of natural pozzolans in the composition of the lime stone extracted. In which, hydraulic lime naturally contains pozzolans which make it waterproof. But Non-hydraulic lime does not contain natural pozzolans to which artificial pozzolans such as ash and brick dust need to be added to make it waterproof.

To find out the type and quality of the extracted lime, a simple field test or laboratory test can be done.

Shell lime is a form of lime (like lime stone) which is obtained by burning the shells of oysters, clams or mussels. A minimum of 60% calcium oxide should be present in the extracted lime. Generally, hydraulic lime possess the higher strength and sets faster. In western countries, grades for lime are used to bring the material into mainstream construction practice like NHL 2, NHL 3.5 (NHL – Natural Hydraulic Lime Grades) but unfortunately in India no such grades are in available in mainstream practice.

The most important step in processing lime is the burning of limestone to form quick lime. This burning process needs to be carried out efficiently in thermally insulated barries as it can decide the quality of lime.

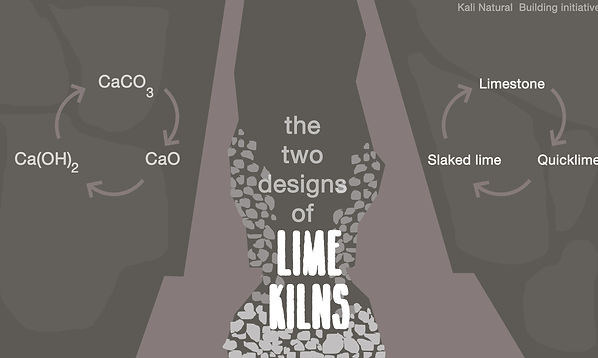

Lime cycle

Once lime is extracted as CaCO3 from the source, it is brought to the lime kilns. Lime kilns are used to burn the extracted lime stone in which the process of burning the lime is known as Calcination. During calcination, release of carbon-di-oxide takes place which gives Calcium oxide (CaO) . After burning, the lime should be kept in air tight containers or bags until it is taken to the construction site. When it is brought to the site, slaking of lime is done to make it usable for construction.

The lime kilns used traditional fuel like dried palm fruits, firewood or coal to burn the stones. The burning of the stones should be done at the right temperature and to the right level. Overburnt or under burnt limestone cannot produce good quality lime. To See more pictures of Lime Kilns Click here.

Lime kilns, which are used for calcination of lime, were present in every village. Calcination is nothing but the process of converting Lime stones to Quick lime. This requires the heating of the stones to 900 degrees centigrade. The use of limestone and shell lime differed on the basis of geographic locations. Places closer to the sea used shell limes and places closer to the limestone reserves used stone lime.

For calcination of lime, two main types of kilns are used in practice : The Intermittent lime kiln and the Continuous lime kiln.

Intermittent Lime Kilns

The earliest and most simplest method of producing lime was done by just layering fuel and limestone stacked together in a mound, covered with clay and slowly burnt. This is one of the permanent kiln type, also known as ‘flare kiln’.

The Intermittent lime kiln most commonly consists of an open-topped cylindrical combustion chamber and a hearth, with one or more draw-holes, also referred to as ‘flues’, ‘stoke-holes’ or ‘eyes’, at the base. Limestone and fuel are mixed and put in the chamber to burn. A vault of stone blocks, resting on an internal ledge, is built over the hearth. The limestone or chalk is stacked above this. The fire, either of wood or coal, is lit at the end of a draw-hole leading into the hearth.

In this Batch type method, the ashes are raked out through the same hole, or a further draw-hole. Flare kilns also use a greater amount of fuel than other kilns, have to be partially dismantled to extract the lime and frequently required relining, so they are not the most cost-effective or convenient method of lime. production.

Continuous Lime Kilns

This Continous type, where limestone can be loaded continuously from the top (accessed through stairs) , as it burns and turns into quick lime, it can be collected at the bottom. Also known as ‘running’ or ‘draw’ kilns.

The kilns are usually built in the form of a pile, made of either bricks ,mud or stones with lime plastering to be a heat resistant structure. Lime and palm fruits are stacked in layers and fired from the bottom. This ignition pushes the hot air through the vent above. The end product (the quality lime) can be collected from the bottom. There are access holes from where the burnt quick lime is procured.

Lime Slaking

After bringing the lime to the site from lime kilns , water is added to slake it into a powdered form. During the process of slaking, Calcium oxide mixed with water produces calcium hydroxide [Ca(OH)2] by releasing a great quantity of heat.

Another efficient way of Slaking is the Hot mixed lime slaking, where Surkhi(brick powder) is mixed with lime before adding water. This type of Slaking gives a high-quality lime mortar.

.jpg)

Lime usage :

-

For stabilization of mud walls such as adobe,CSEB etc., 8-10% of lime is mixed with mud.

-

Lime is used as a good termite repellent.

-

As mentioned earlier, hydraulic lime offers waterproofing quality.

-

Lime mortar can be used as an alternative to cement mortar in walls and foundation.

-

Lime plasters provide thermal comfort and aesthetically pleasing wall surfaces.

Lime as construction material | Lime plasters | Kali natural buildings initiative